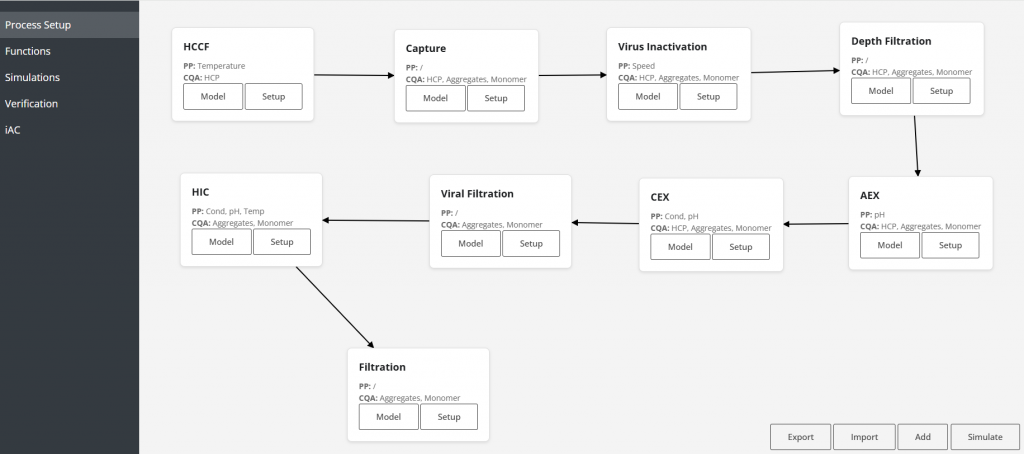

An Integrated Process Model (IPM) leverages on the entirety of process knowledge (i.e. both experimental and manufacturing data) from all the different steps to quantitatively understand and predict how changes affect the final product. As a relatively novel technique it is used as part of process validation for setting up a control strategy for the manufacturing process. (cf. ICH Q6B)

Some advantages of IPM:

- Optimize the process in function of trade-off between yield and clearance.

- Guide further design of experiments (DoE) based on process optimisation results.

- Visualize process conditioned on out-of-specification samples to find bottlenecks in the process.

- Assess process sensitivity, risk and robustness by what-if analysis and simulation.

- Determine intermediate acceptance limits for control strategy based on product requirements.

For demonstration purposes, one part of IPM is the validation of assays based on product specification. A free to use application is available here.

Contact us for more information.